Table of Contents:

Table of Contents:

Electrostatic discharge (ESD) is the sudden flow of electricity between two electrically charged objects, more specifically, it is a high-current event (1–15 A) with a short duration (1–100 ns)[1]. ESD can be caused by contact, an electrical short, or when a current flows through an electrical insulator and the voltage applied across it exceeds the breakdown voltage.

Controlling ESD is particularly important in certain industries and specialized spaces. Along with the implementation of an ESD policy that includes compliance plans for clothing, footwear, wrist straps, work surfaces, and shielding bags, the installation of ESD flooring is key. Here we explore the areas where ESD flooring is most crucial for safety, productivity, and cost savings.

This ESD floor is being installed inside a production room at a medicine manufacturing facility, and will safeguard equipment and personnel against potential electrostatic discharge.

1. Research & Development Spaces

Pharmaceutical and technology industries use seamless, epoxy ESD flooring in their R&D spaces due to the equipment and substances they are working and surrounded with on a daily basis. Due to the flammable substances and chemicals that require specific precautionary measures when handling, an ESD floor significantly reduces the chance and spread of fire. In addition, particles such as grain and sugar, as well as fine powders commonly used in pill manufacturing, can float in the air and become combustible. ESD floors are installed to protect against such occurrences.

2. Clean Rooms in Electronics Manufacturing Facilities

Electrostatic buildup can spell disaster for an electronics manufacturing company. Since nearly any material can cause electrostatic buildup (fabric, metals, glass, even skin) it is important to use all precautions to avoid it when handling sensitive electronic components. Clean rooms where integrated circuits, hard drives, and other components are manufactured and serviced, require precautions such as special footwear, clothing, and floors that provide a safe outlet for electrostatic buildup. Friction within a clean room can generate static discharge or static buildup which damages circuit boards and other sensitive equipment. Even the smallest jolts of static discharge can cause this to happen. Investing in a seamless, epoxy ESD flooring system saves a company from having to replace damaged components.

ESD flooring protects sensitive equipment for possible electrical malfunction.

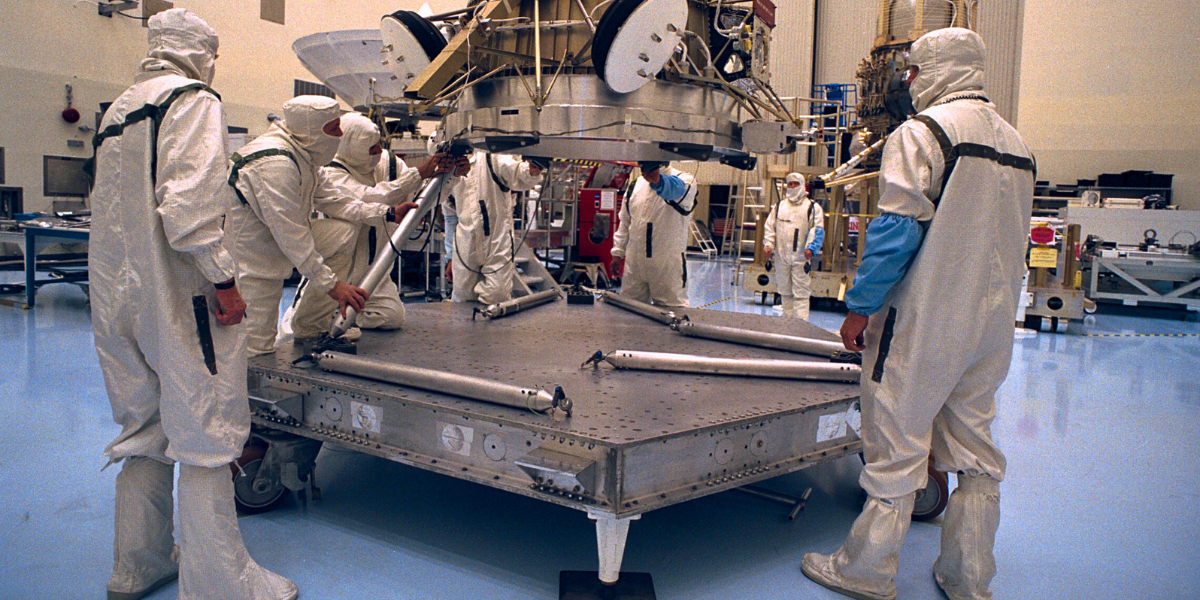

3. Aerospace Assembly Areas

Aerospace assembly requires several employees to be working in one space. These workers fabricate, assemble, install, test and inspect the many parts which make up a modern airplane. Without ensuring proper safety through ESD flooring, the friction generated by closely working bodies can cause a triboelectric charge. When materials become electrically charged, parts can become damaged, and employees may suffer from unexpected static and sparks that could potentially be life threatening. With seamless, epoxy ESD floors, the aerospace industry saves on lost time and money due to product damage and staff injury, and more importantly, human life.

Stonlux ESD flooring offers reliable protection against static discharge in automotive manufacturing facilities.

4. Auto Manufacturing Assembly and Test Labs

High-tech test labs and automotive assembly floors are constantly exposed to wires, car parts, and charging instruments. Conductive flooring is necessary to defend against electrostatic discharge. Merely sliding a plastic tool across a metallic surface can cause damaging static. In order to protect auto workers and the auto parts they test and assemble, seamless epoxy ESD flooring is a must.

5. Solvent Storage Areas

Facilities that use solvents such as paint thinners, acetone, and toluene must take precautions to store and handle these substances properly due to their high flammability. Due to the vapors these substances give off, they are extremely volatile and can spell disaster should they come in contact with an ignition source (an electrical charge generated by friction). ESD flooring is necessary in solvent storage areas to dissipate this charge and protect people and property from fire and explosion.

Does your facility require ESD flooring protection? Contact us to set up a site visit today.

Related Articles

Loving this Content?

Subscribe to upcoming topics!