Low Odor Flooring

Keeping odor to a minimum is an obvious consideration when installing any materials in industrial or commercial environments. Everyone wants to consider health and follow regulations to eliminate harm to personnel and limit the disruption of operations. When a floor is being installed it is imperative the installer takes all necessary precautions, knows the materials, and uses proper ventilation and equipment regardless of the materials.

A low-odor flooring installation means less disruption to your business!

Maintain productivity by minimizing disruptions to daily operations by choosing a company that manufactures and installs low-odor flooring. Stonhard's low-odor solutions reduce air quality concerns, allowing installations to take place during business hours with minimal impact.

What is a Low-Odor Flooring Installation?

Stonhard has many different options for flooring that have specific benefits. We work with customers to help them select the right product based on installation limitations such as low odor, as well as the right product to perform in the facility's environment. Stonhard has low-emissions formulations and the expertise to manage odor on job sites with proper tenting and ventilation as needed.

The Benefits of Low-Odor Flooring

Low-odor flooring offers many benefits, such as:

- protecting the health of employees and visitors during installation

- fewer distractions for employees due to chemical odors

- advantages to installation in areas where ventilation is not optimal

- avoiding costly shutdowns

Low-Odor Flooring Installations are Perfect For:

Explore a Project

Explore projects where low-odor flooring made a difference. Dive into real-world examples where our expertise delivered flooring solutions built to last in the most demanding environments.

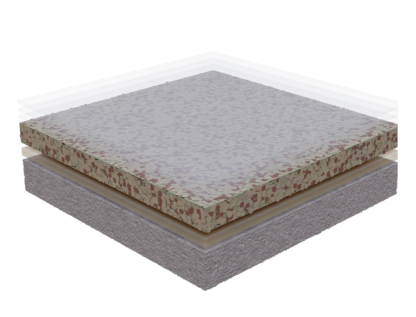

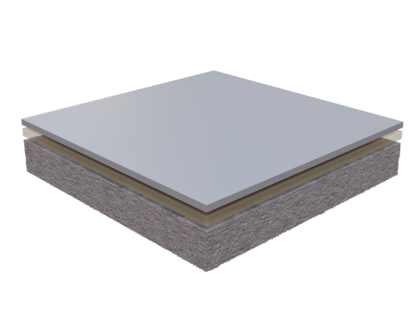

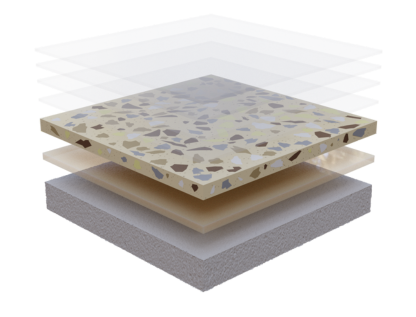

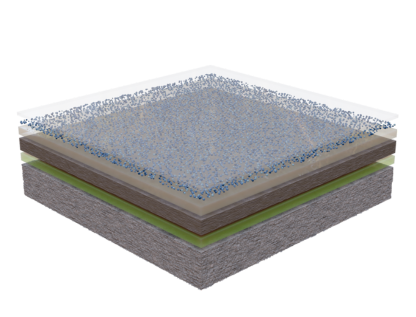

Recommended Low-Odor Flooring

Stonhard formulates floors for every environment, including those requiring low-odor properties. Our team of Territory Managers, Architectural and Engineering Representatives will assist you in choosing the best product for your environment with the look you desire.

FAQ

Got questions? We've got answers. This FAQ section covers the most common inquiries about low-odor flooring to help you make informed decisions.

Low odor seamless floors are flooring systems designed to emit minimal or no unpleasant odors during installation and use. They are commonly made from epoxy or polyurethane resins and are applied directly onto a substrate to create a seamless, durable surface.

- Improved Indoor Air Quality: Minimal odors mean reduced VOC emissions, contributing to healthier indoor environments.

- Enhanced Comfort: They allow for uninterrupted use of the space during and after installation, without strong chemical smells.

- Environmentally Friendly: Many products are formulated to meet strict environmental standards, making them suitable for green building certifications.

While some products may be both low VOC and provide a low-odor installation, this is not always necessarily the case. A product can be low VOC but still have a noticeable odor during installation. While VOCs contribute to strong smells, other chemicals and ingredients in adhesives, sealants, or coatings can also produce odors. For example, some water-based adhesives have strong smells despite being low-VOC.

Even low-VOC products can release short-term odors as they cure, especially in enclosed spaces with limited ventilation. Ensuring good ventilation during installation is key for low-odor installations.

Certain application methods can expose more product to the air, making odors more noticeable.

These floors are ideal for environments where odor-sensitive conditions are a concern, such as:

- Hospitals and Healthcare Facilities: Ensuring patient comfort and cleanliness.

- Commercial Offices: Minimizing disruption to daily operations.

- Residential Buildings: Providing a comfortable living environment without strong chemical odors.

Installation typically follows these steps:

- Surface Preparation: Ensuring the substrate is clean, dry, and free of contaminants.

- Application: Mixing and applying the low-odor resin system according to manufacturer guidelines.

- Curing: Allowing sufficient time for the floor to cure and harden, with minimal to no odor emissions.

Yes, they offer similar durability to traditional seamless floors, with high resistance to impact, abrasion, and chemicals, depending on the specific product and application.

Regular cleaning with mild detergents and periodic inspections to address any wear or damage are typically sufficient. Consult manufacturer recommendations for specific maintenance guidelines.

Yes, they offer similar durability to traditional seamless floors, with high resistance to impact, abrasion, and chemicals, depending on the specific product and application.

Related Flooring Features

Expert Guides & Resources

The WELL Building Standard: Solving Problems for Humans and the Environment

With a growing focus on making buildings healthier for occupants, the WELL Building Standard has gained worldwide acceptance as a rating system for improving the health and well-being of building occupants. Learn more about WELL and its material concepts, including low VOCs, in this insightful article.

Commercial Buildings

Commercial Buildings