Thermal Shock/Cycling-Resistant Flooring

Floors designed to stand up to extreme temperatures and extreme changes in temperature.

Rapid temperature changes, who likes that? Not the typical floor. Then again, Stonhard is not your typical floor.

Hot, cold, and hot again. Extreme temperatures can wreak havoc on floors -- but not ours. We engineer floors to meet the challenges of rapid temperature changes and extreme temperatures in spaces like commercial kitchens, food processing, breweries, and industrial spaces. No cracking, delaminating, or warping.

What is Thermal Shock and Cycling Resistant Flooring?

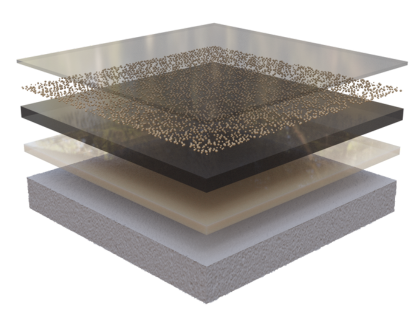

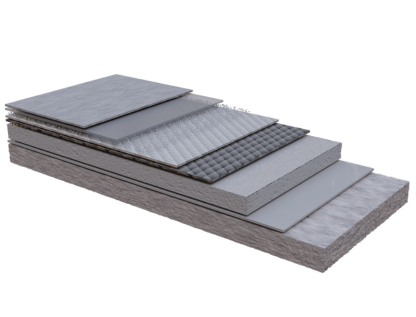

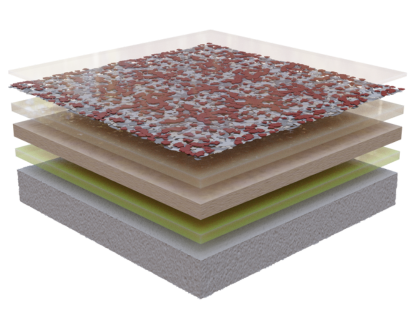

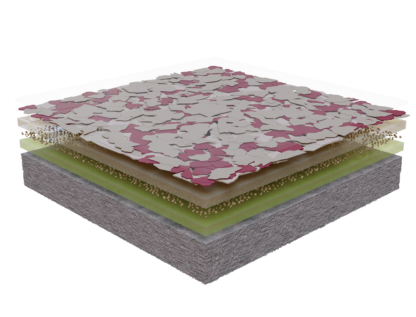

Thermal shock and thermal cycling-resistant flooring is formulated to withstand extreme temperature changes without cracking, delaminating, or deteriorating. These properties are crucial in environments where flooring is exposed to sudden or repeated temperature fluctions.

Thermal shock is where sudden, drastic temperature shifts take place. A cold floor can experience thermal shock when it comes into contact with hot liquids, steam, or boiling water. Without being designed to withstand thermal shock, a floor may crack or separate due to rapid expansion and contraction.

Thermal cycling happens with repeated exposure to heat and cooling cycles over time. Floors constantly exposed to ovens, refrigeration, or steam cleaning can wear and lose structural integrity.

High-performance seamless urethane flooring can expand and contract without failure.

The Benefits of Thermal Shock and Cycling Resistant Floors

In certain environments, protection from thermal shock and cycling are critical to the longevity of a floor and to avoid floor failure. Benefits of thermal shock and cycling resistant flooring are:

- Preventing cracking of the floor

- Saving lost time and money in the repair or replacement of floors

- Providing good working conditions for employees

- Maintaining floor aesthetics

Thermal Shock and Cycling Resistant Floors are Perfect For:

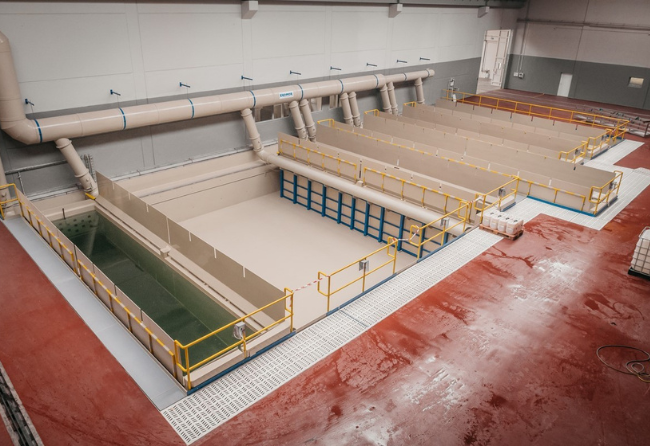

Explore a Project

Explore projects where thermal-shock and cycling-resistant flooring made all the difference. Dive into real-world examples where our expertise delivered flooring solutions built to last in the most demanding environments.

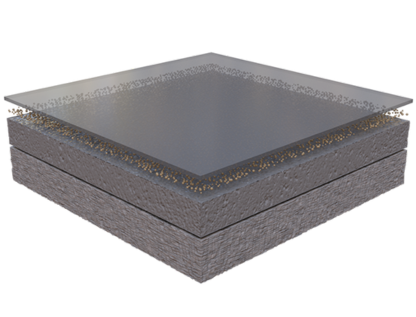

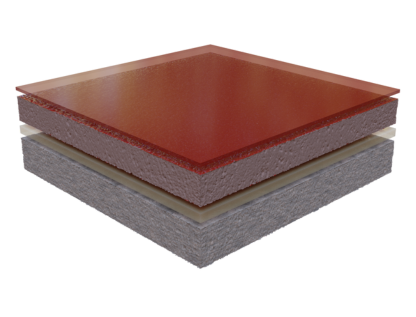

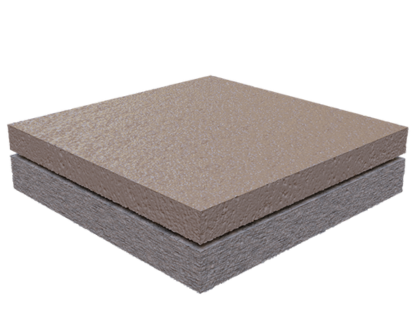

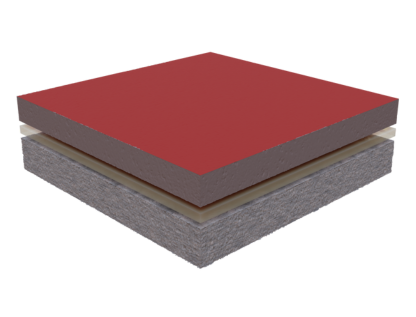

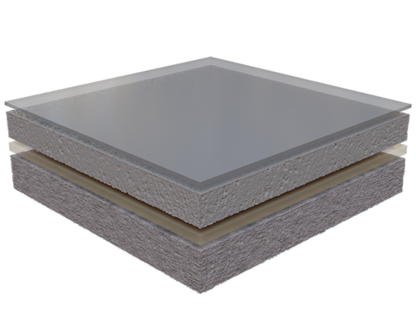

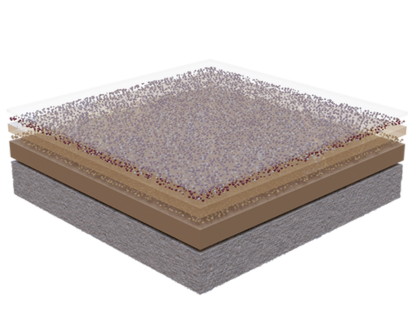

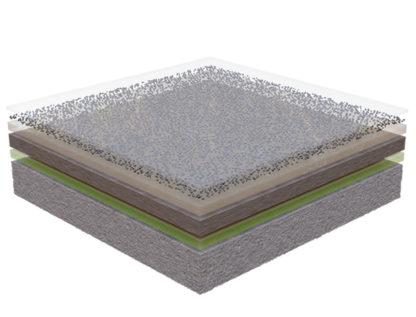

Recommended Thermal Shock and Cycling Resistant Flooring

Stonhard formulates floors for every environment, including those requiring thermal shock and thermal cycling-resistant properties. Our team of Territory Managers, Architectural and Engineering Representatives will assist you in choosing the best product for your environment with the look you desire.

FAQ

Got questions? We've got answers. This FAQ section covers the most common inquiries about thermal shock-resistant flooring to help you make informed decisions.

Thermal shock resistant floors are designed to withstand rapid temperature changes without cracking, delaminating, or deteriorating. These floors are made from materials that can handle extreme heat and cold, making them suitable for environments where such conditions are common.

Regular cleaning with a mop or soft nylon brush and with a neutral pH cleaner are usually sufficient. Avoid using harsh chemicals or abrasive tools that could damage the floor.

Thermal shock-resistant floors can be made slip resistant by incorporating anti-slip additives in the topcoat. This ensures safety even when the floor is wet or greasy.

Yes, these floors can be customized with different colors, patterns, and finishes to meet specific aesthetic and functional requirements.

Related Flooring Features

Expert Guides & Resources

The Top 5 Stonhard Products for the Food & Beverage Industry

Learn how Stonhard formulates products to meet the demands of specific food and beverage manufacturing areas. From food production and meat packing to CIP areas, freezers, dry storage, packaging and more.